Get in touch

555-555-5555

mymail@mailservice.com

Blog.

By algenuity

•

11 Sep, 2019

Genetic modification isn’t the only way to enhance commercially desirable traits in microalgae. Directed evolution – which uses successive rounds of conditional selection to isolate highly specialised variants – is an effective strategy to improve properties of an organism without using genetic recombination or undertaking bioprospecting. Directed evolution has already played a vital role in creating Algenuity’s groundbreaking Chlorella Colours ® platform by producing chlorophyll-deficient variants of its original, high performing wild type Chlorella vulgaris strain with improved organoleptics. But the potential of this widely applicable method doesn’t stop there. Next week, at the 2019 Algae Biomass Summit in Orlando, Algenuity’s Chief Scientific Officer Alex Pudney – a specialist in strain development, metabolic engineering and synthetic biology – will be highlighting an example of the potential global impact of using directed evolution to improve algal strain characteristics for the aquaculture sector. Directed evolution promises to benefit many algal applications, not least the aquaculture industry where the rising global population is driving demand for ever-greater productivity. Microalgae are a nutritionally important food source for fish at all stages of development, and are also used to produce the copepods that are fed to various species of marine fish. A good-quality omega-3 oil content in such fish is dependent on nutritional quality of copepods, which, in turn, is directly related to the algae they are fed. Efficient production of high-quality microalgae is therefore crucial but is affected by light and temperature, making the method – and associated costs – of such cultivation an important consideration, especially for aquaculture in challenging climates. In a recent case study that Alex will expand on in his presentation, Algenuity produced a temperature-tolerant strain of Tisochrysis lutea , a microalga used extensively in copepod production. While T. lutea is normally cultivatable up to 32 °C, improved mutants grew productively at 35 °C. After an additional round of selection, mutants showed a ten-fold increase in biomass productivity when tested in Algem ® photobioreactors under simulated light and temperature conditions for the United Arab Emirates in June, where daily temperatures can reach 39 °C/102.2 °F. Importantly, the composition of omega-3 polyunsaturated fatty acids in the algae was not adversely affected. This work – conducted on Algenuity’s Algem ® photobioreactor – demonstrates the expertise of Algenuity in the algal sector, and is the first demonstration of directed evolution in a real world scenario. Watch this space for further developments in the project! Alternatively, to see how directed evolution could be applied to your application, contact us at info@algenuity.com.

By algenuity

•

20 Jun, 2019

I’m originally from Lebanon, where I gained both a BSc and a Master’s degree in biochemistry at the Lebanese University Faculty of Sciences, and a second Master’s in applied biotechnology from the Lebanese University-Graduate School of Science and Technology (EDST). During my applied biotechnology Master’s, I worked on macroalgae and became fascinated with marine biotechnology and its application to ocean resources. I passionately wanted to continue in this field, and applied for a PhD in bioprocess engineering at the University of Nantes in France, working on microalgae for biofuel production. After my PhD, I worked as a lecturer and researcher in the department of Process and Bioprocess Engineering at Polytech Nantes – the Graduate School of Engineering of the University of Nantes. I continued in my role as a lecturer while undertaking postdoctoral research at the University of Nantes, where I was involved in a joint project with the Center for Sustainable Development at Qatar University. Our aim was to screen and characterise thermotolerant microalgae strains showing promise for large-scale outdoor production for feed, food and fuel applications in Doha, Qatar. After three years in academia, I wanted to move into the ‘real world’ and put my research into practice by developing practical applications for the technology. That led me to Algenuity. I went to Algenuity’s website, where I read about the work it was doing and the projects it was involved in. It was just so exciting and motivating, exactly what I wanted to do and the sort of company I wanted to be a part of. I successfully applied for a senior scientist position and started in July last year. I’m chiefly involved in process development, improving the productivity of algal strains by directed evolution, using a DoE approach to optimise our algal bioprocesses. What I love is that I’m working on a number of projects using different algal strains for various applications. It’s amazing how you can use photobioreactors to optimise your processes by adjusting the lighting and temperature conditions, and the pH and composition of the culture medium, to see how the productivity of the strain is affected. Light and temperature are particularly crucial factors, especially when you think about scaling up, and this is the big advantage of the Algem® technology. It’s possible to simulate conditions anywhere in the world, to see how algal growth in an outdoor environment is likely to be influenced by fluctuations in these parameters, or the changing seasons, and use this knowledge to improve the strain. Algae have so much untapped potential. They are a sustainable resource rich in vitamins, proteins and carbohydrates, and good for the environment too, as they consume carbon dioxide while growing something from the biomass, which really excites me. Working with microalgae is great, it combines all my interests and really excites me. You start with a biologic strain, improve it and get to know more about it, and then put it into your process, making more adjustments to get the best productivity before scaling up. I just love this work.

By algenuity

•

01 Apr, 2019

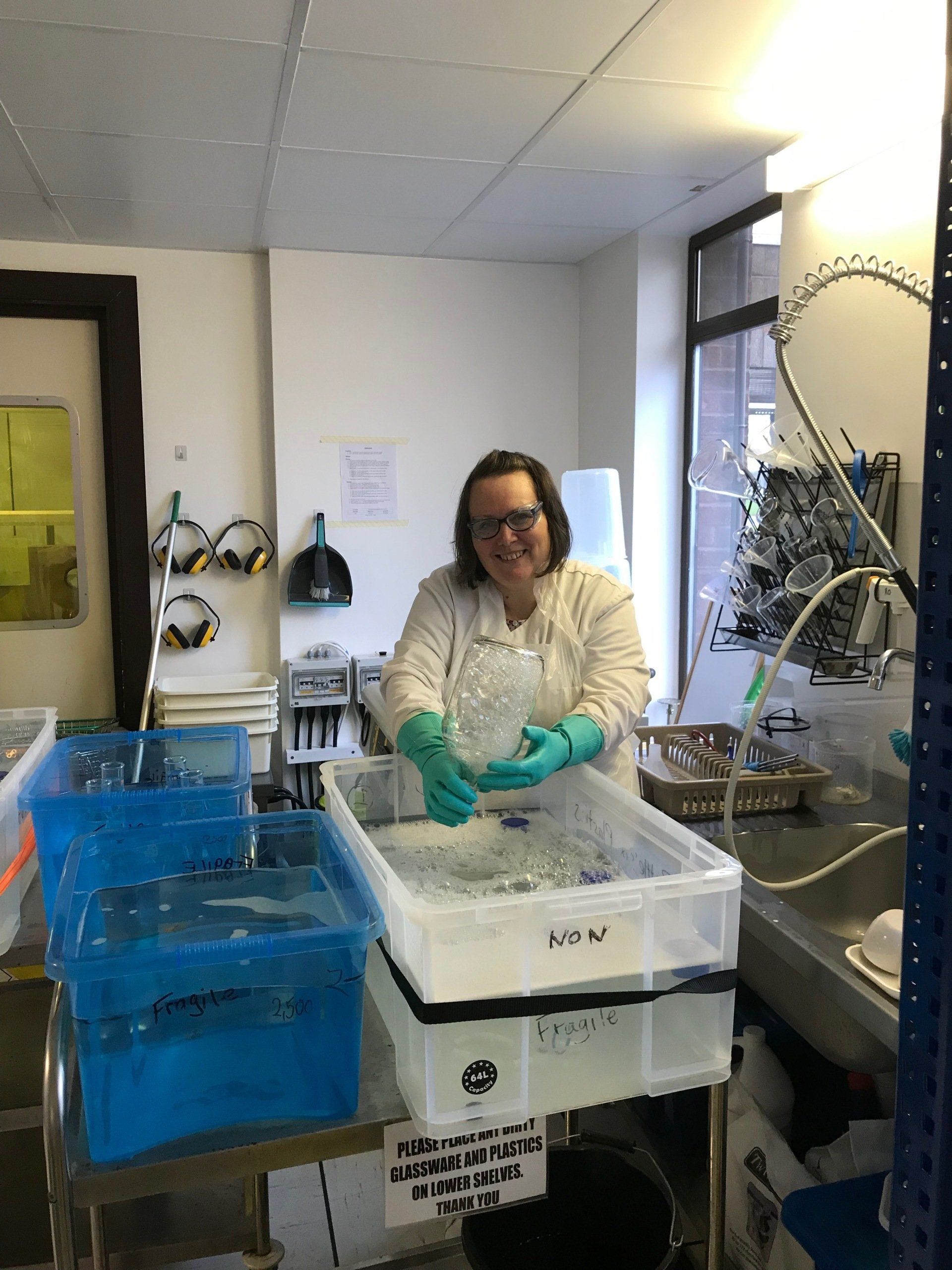

Truth be told, scientists can be an untidy bunch. Throw algae into the mix and it only gets worse, and that’s where I come in. I’m responsible for making sure that all the glassware and plastics are clean and available for use in our daily experiments. Washing the labware is quite a long and involved process and takes around four hours from start to finish. Several bleaching, disinfecting and rinsing steps are needed – with both mains and reverse osmosis water – followed by baking in an oven to dry. Afterwards, I clean the items with isopropyl alcohol to remove any pen markings and cover them with aluminum foil to keep them sterile. Sometimes a plastic flask is accidentally baked at too high a temperature, and the resulting melted mess is no good in the lab but makes an appealing ornament on my mantlepiece. My working life has been quite eclectic. After 13 years in retail, 14 years in a factory packing heating thermostats, a little time ironing from home and then working in a funeral parlour, it didn’t seem all that odd to add algae cleaning to the list. Andrew needed someone to do just a few hours of washing a week – nothing too taxing I was told! – and six years later, I’m working almost solidly at the sink for two and half days, cleaning up to 100 flasks a day, not to mention the much larger 10 litre vessels. Being trained by Andrew and Sam, I naturally have the same high expectations for cleanliness. If something is left by my sink, it gets cleaned, and sometimes I like to teach my colleagues a little cheeky lesson in tidiness if they leave a flask casually lying around! When someone new arrives, it’s my job to convert them to our way of thinking. It seems like students often think they don’t need to wash their lab coats but, under my watch, they soon learn differently. The company is very supportive of its staff. When I first started working at Algenuity, I thought that I’d do my job and then go home and forget about it. But you get to know everybody and appreciate the family feel, making it enjoyable to come into work every day. No doubt if we continue to grow, there’s the possibility that we’ll need another person to help me. And obviously, one day, I might like to retire. Andrew says I’ve got to give him three years warning so he can train somebody else. We shall see!

By simon.algenuity

•

30 Jul, 2018

I have been married to an algal biologist for thirty years, so working at Algenuity I get algae morning, noon, and night! But rather than spending my days in the lab, I’m more likely to be found at my desk behind a computer or in a meeting room. As operations manager, it’s my role to keep everything ticking over and to free the scientists to focus on what they do best – research and development. I help to bridge the gap between our science and the wider world, ensuring that our business runs smoothly. There’s no doubt that my job can often feel like juggling lots of balls; finance, HR and administration all come under my remit, and I’m up and down the stairs like a yo-yo – it’s good for my step count I’m sure. I often have to keep track of everyday jobs while planning future events, such as making sure an Algem® is ready and shipped for our next show. I’ve been involved in this type of role for the past 20 years, so managing multiple demands in a small company feels a little like second nature. I unofficially like to think of my role as ‘clarity provider.’ The challenge of working in a start-up is that all the processes have to be developed from scratch and adapted as the company grows. Part of my role has been to help to cement the way we work as a company and nudge people in the right direction. When I came on board three years ago, I was able to free up Andrew and others who, at the time, were stretched between the lab and the office. It’s been a huge help, allowing them to pursue their interests without worrying about all the other stuff – such as keeping track of financial transactions or submitting grant claims every quarter – that still needs to be done. After all, algal strain engineering is a world apart from employment law! Algenuity is very much a family company – you can feel the vibe when you walk in – and maintaining this distinctive culture will be crucial as we continue to grow. It’s an exciting prospect, and I look forward to being even busier and keeping up with the pace of change. At the end of the day, I’m quite happy to let people specialise in what they do, because they do that better than I ever could. I’m very much a generalist, and I think that a company needs both types of people to succeed.

By algenuity

•

19 Jul, 2016

Tom Butler is finishing up a 9 month internship with Algenuity and will be headed to the University of Sheffield this autumn to start his Ph.D. under the supervision of Dr Raman Vaidyanathan. Mike Yates, our Head of Business Development at Algenuity, sat down with Tom to chat about his experience at Algenuity. You have had a long-standing interest in the environment and marine studies. Can you share a little bit more? I have always loved the ocean and marine life. For my undergraduate degree, I followed this passion and studied Marine Biology at Newcastle University. And outside the lab, I have been an avid scuba diver. Earlier this year, I travelled to Sri Lanka to go on a dive trip, and in two weeks, I am going out for a dive trip to Malta! Brilliant. So how did you get into algae? Learning from and working with Gary Caldwell at Newcastle really opened me up to the positive potential for algae for real world issues and how algae can provide sustainable solutions to energy and food challenges. At Newcastle, we conducted several practicals on micro- and macroalgae. This motivated me to apply to SAMS (Scottish Association for Marine Science) for their MRes programme in Algal Biotechnology. How was the experience at SAMS? Would you recommend the programme? I thoroughly enjoyed the masters year at SAMS. I deepened my microbiology knowledge, expanded my toolset, and developed my algal research skills. I did my dissertation on "An alternative strategy for astaxanthin production using Haematococcus pluvialis ". Yes, I would definitely recommend the SAMS Algal Biotechnology MRes programme . It provided me with a solid foundation for this year’s industrial internship and will prove to be invaluable for my future Ph.D. studies. It was also great to be mentored by leading algal biologists, such as Professor John Day and Dr Michele Stanley. I also really loved being in the SAMS location of Oban, Scotland. It is so beautiful there, and it is great for adventure enthusiasts. What has been some of the highlights of your Algenuity internship? I have enjoyed working with the extremely talented scientists and the multidisciplinary team here at Algenuity and Spicer Consulting. It is such a dynamic and innovative environment. It has been particularly great to be specifically mentored by Michiel Matthijs, the CSO of Algenuity. I have learned a lot about rigorous experimental design, analysis of data, and drawing conclusions for the purpose of either future papers or patents. Michiel has also taught me how to use some of the key equipment in the labs, including the liquid handling robot and the 384-well qPCR machine. It has been a lot of fun. Any other highlights? I enjoyed growing my algal molecular biology skills and learning about genetic manipulation of algae. Algenuity is the perfect place to learn about this. I worked mostly with Phaeodactylum tricornutum and developed and worked with tags, such as the uracil 3 marker and the halo tag. I also have enjoyed producing the Algem application notes . It has been great to work with a large variety of algae and optimise growth conditions for the algae. I particularly enjoyed working with extremophilic species of algae, such as the acidophile and thermophile, Galdieria sulphuraria ; the alkaliphile, Arthrospira platensis ; and the psychrophile, Fragilariopsis cylindrus . Did you have a particular favourite application note? My favourite application note was studying the locally bioprospected Haematococcus pluvialis strain . As I mentioned earlier, I did my dissertation on Haematococcus pluvialis . What made this application note particularly interesting was that one of the constraints of industrially produced astaxanthin is the temperature range. Optimal growth for normal Haematococcus pluvialis strains is usually between 20 to 25 degrees Celsius. If the temperature is higher, cells in the green stage transition to cysts/aplanospores, and this limits biomass yields and flexibility. At Algenuity, we have isolated a Haematococcus pluvialis strain that thrives at 30 degrees Celsius and remains in the green stage without the induction of aplanospores. This increased temperature range has positive industrial implications. Overall, it shows the power and potential of bioprospecting. A bit of a geeky algae question – is Haematococcus pluvialis your favourite alga? Mine is Euglena gracilis . Actually, my favourite alga is the diatom Phaeodactylum tricornutum . I am actually going to be studying Phaeo for my upcoming Ph.D. at Sheffield. I love how Phaeo has a fast growth rate and is less sensitive to contamination than other microalgae. It is like a weed and just grows and grows! I also appreciate that the genome has been sequenced, that the molecular toolbox continues to develop and improve, and that there are transformation approaches available. With your extensive work with the Algem application notes, it is fair to say that you have used the Algems more than any previous intern we have had at Algenuity. What particularly do you like about the Algem? The tightness of errors bars for growth and environmental parameters such as temperature, light, and pH is hands down the best thing about the Algem. Coming from a marine background, I have found it really useful to monitor and control the pH level at a set pH range or pH level. For example, seawater often has a set pH, and it is very useful to simulate conditions in the alga’s native environment. I also appreciate the geographical modelling feature of the Algem where you can pretty much model any daylight and temperature profile from around the world by inputting a longitude and latitude value. From an ecological point of view, it is powerful to be able to study the organism under environmental parameters close to its true environment, including cloud cover! I have also valued how you can sample simultaneously over a planned time course while the Algem is running through a sterile syringe and vacuum manifold system. Michiel and I did an extensive qPCR experiment investigating circadian rhythms and the disruption of these systems using Phaeodactylum tricornutum using this technique. Out of curiosity, did you use any particular geographical regions in any of your Algem experiments? I did an experiment with Chlorococcum novae-angliae modelled in its place of origin in the California, USA area. I also studied Desmodesmus abundans and Desmodesmus subspicatus modelled in different locations of India and China to look for areas with low labour and land costs and locations that could be useful for bioremediation. You are headed up to the University of Sheffield this autumn to begin your Ph.D. in the lab of Dr Raman Vaidyanathan . Can you share what you will be studying? I will be studying Phaeodactylum tricornutum as an aquaculture feedstock to replace fishmeal that is used in the process. The emphasis will be on optimising protein, fatty acids, and carotenoids. I have a particular interest in EPA and fucoxanthin. I will be looking at both non-GM and GM tools. I am very excited to get started at Sheffield! As a closing question, what advice would you give to students who are interested in algae? The microalgae sector is multidisciplinary, and it needs skills from many fields including molecular biology, engineering, ecology, biochemistry, and business. You can be involved! As far as practical tips, when pursuing a new project or idea, make sure to do background reading. It is so important. As far as the algae industry, the limit to success is the economics. The economics should always be in the back of your mind when doing research. Because the field of algae research can be so broad, I find it helpful to keep a focused approach. I like to try to see things through a problem-solution lens. I try to make sure I define a problem when beginning a project. It makes pursuing a solution much easier! And lastly, look out for good mentors. I have been so fortunate to have great mentors, such as Gary Caldwell, John Day, Michele Stanley, and Michiel Matthijs. They have been pivotal in helping me to grow professionally and helped to accelerate my career. Thanks again Tom for your time and for being willing to do this. You have been a valuable member of our team, and we will miss you. We wish you the best at Sheffield!

GET IN TOUCH

to see how our algal and scientific capabilities can transform your application

© 2024

Algenuity Limited

Registered in the United Kingdom No: 12456594

Site design by Ibby Tarafdar Creative

© 2024

Algenuity Limited. Registered in the United Kingdom No: 12456594

Site design by Ibby Tarafdar Creative